- Industrial LCD display

-

Industrial Products

- DC Servo Drive

- AC Servo Drive

- other

- Heidelberg

- FANUC

- IFM

- Meter

- CCD

- Membrane Keypad

- Film

- YOKOGAWA Module

- Card

- ABB

- MITSUBISHI

- FANUC

- KEYENCE

- BECKHOFF

- Honeywell

- HOLLYSYS

- FUJI servo drives

- HP

- solenoid valve

- thermostat

- Siemens adapter

- color oscilloscope

- Fujitsu connector

- CHELIC

- SMC

- CISCO Module

- INTEL

- Key board

- FAIRCHILD

- Motherboard

- Board

- Bearing

- other

- Control Panel

- Contactor

- Circuit

- OMRON

- Relay

- Controller

- Photoelectric Switch

- Photoelectric Sensor

- Original

- Fan

- Motor Driver

- Limit Switch

- Amplifier

- power supply

- LENZE

- Cable

- Encoder

- Sensor

- Transformer

- Fiber Optic Sensor

- Protection Relay

- Temperature Controller

- Proximity Switch

- Switch Sensor

- Siemens

- Industrial board

- HMI Touch Glass

-

HMI Full Machine Whole unit

- OMRON HMI Touch Panel

- Siemens HMI Touch Panel

- Mitsubishi HMI Touch Panel

- Allen-Bradley automation HMI Touch Panel

- DELTA HMI Touch Panel

- EVIEW DELTA HMI Touch Panel

- KINCO DELTA HMI Touch Panel

- HITECH HMI Touch Panel

- WEINTECK HMI Touch Panel

- TECVIEW HMI Touch Panel

- WEINVIEW HMI Touch Panel

- PRO-FACE HMI Touch Panel

- SIMATIC HMI Touch Panel

- AMPIRE HMI Touch Panel

- HEIDELBERG HMI Touch Panel

- PANASONIC HMI Touch Panel

- PATLITE HMI Touch Panel

- KYOCERA HMI Touch Panel

- KEYENCE HMI Touch Panel

- WEINVIEW HMI Touch Panel

- HITECH HMI Touch Panel

- FUJI HMI Touch Panel

- HAKKO HMI Touch Panel

- SCHNEIDER HMI Touch Panel

- SAMKOON touch panel

- other

- Module

- lcd inverter

- Membrane Keypad Switch

- Winni Touch Screens

- Frequency Inverter

- Servo Motor

- PLC

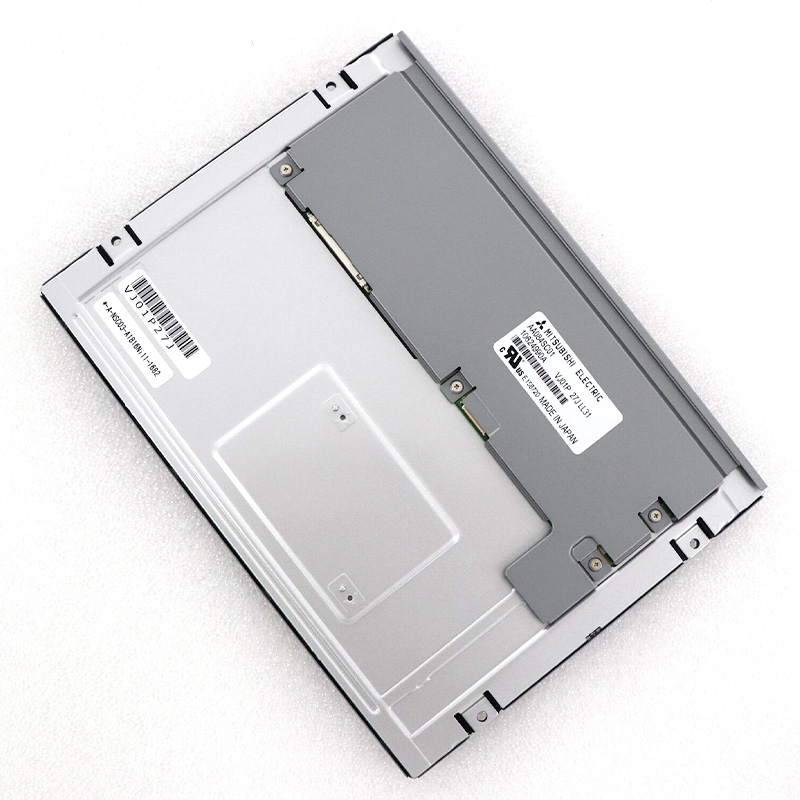

In the intricate world of industrial and specialized display technology, certain components become the unsung heroes behind reliable and enduring systems. One such component is the 8.4" 800x600 AA084SC01 LCD panel, a display module intrinsically linked with equipment manufactured by Mitsubishi Electric. This article delves deep into this specific panel, moving beyond a simple specification sheet to explore its technological significance, typical applications, and the critical considerations for sourcing and integration.

For engineers, procurement specialists, and maintenance technicians, understanding this panel is not merely about finding a screen. It's about ensuring the continued operation of vital machinery. The AA084SC01 is more than just a commodity LCD; it is often a direct replacement part designed for seamless compatibility with Mitsubishi's ruggedized human-machine interfaces (HMIs), programmable logic controller (PLC) terminals, and other industrial control systems. We will examine its core characteristics, the environments it serves, and its role within the broader ecosystem of industrial automation.

Decoding the AA084SC01: Core Specifications and Technology

The alphanumeric code AA084SC01 holds the key to the panel's identity. The "8.4"" denotes the diagonal screen size, a popular format for compact industrial terminals. The native resolution of 800 x 600 pixels, known as SVGA, offers a balanced compromise between detail and legibility, crucial for displaying schematic diagrams, control parameters, and diagnostic data without excessive UI clutter.

Digging deeper, this panel typically employs a TFT (Thin-Film Transistor) active matrix technology with a standard RGB stripe arrangement. The "AA" prefix often indicates a specific product family or generation within the manufacturer's portfolio. Key performance parameters include its aspect ratio (4:3, the standard for industrial applications of its era), brightness levels suited for indoor industrial lighting, and viewing angles that allow for clear visibility from various operator positions. Understanding these specs is the first step in validating its suitability as a replacement.

Primary Applications in Mitsubishi and Industrial Ecosystems

The AA084SC01 panel was engineered for durability in demanding settings. Its primary home is within Mitsubishi's own suite of industrial automation products. You will commonly find this panel integrated into the GOT (Graphic Operation Terminal) series, which serves as the visual and interactive front-end for Mitsubishi PLCs like the MELSEC series.

These terminals are the nerve centers on factory floors, controlling processes in manufacturing, packaging, automotive assembly, and water treatment plants. Beyond branded Mitsubishi units, this display module was also adopted by third-party manufacturers building compatible or custom HMIs for systems centered on Mitsubishi controllers. Its reliability made it a de-facto standard for mid-size displays in 2000s-era control systems that remain in operation today, underscoring the need for ongoing component support.

The Critical Role of Compatibility and Direct Replacement

When a display fails in an active production line, the replacement process is not as simple as purchasing any 8.4-inch screen. The AA084SC01 is a direct replacement panel, meaning it is designed as a form-fit-function equivalent to the original component. This compatibility encompasses several non-negotiable factors.

First is the physical form factor: mounting hole positions, bezel dimensions, and overall thickness must match precisely. Second is the electrical interface: the connector type, pinout, and signal timing (typically LVDS or TTL) must be identical. Finally, the mechanical interface, such as the position of the control board (often attached to the rear), must align. Using a non-compatible panel can lead to installation failure, signal mismatch, or damage to the host terminal, making the exact match paramount.

Sourcing Challenges and the Aftermarket Supply Chain

As an older panel model, sourcing the genuine AA084SC01 presents distinct challenges. Mitsubishi may have discontinued direct sales or phased it out in favor of newer models. This creates a vital niche for specialized aftermarket distributors and suppliers who focus on obsolete and long-lifecycle industrial components.

The supply chain for such parts operates differently from consumer electronics. It involves inventory from original factory overruns, certified refurbishments, and sometimes new-old-stock (NOS). Procurement professionals must vet suppliers rigorously, prioritizing those who offer testing certifications, warranty coverage, and technical support. The market also sees the availability of "compatible" panels, which necessitates even more careful scrutiny to ensure they meet all the direct replacement criteria outlined previously.

Technical Considerations for Integration and Maintenance

Successfully integrating a replacement AA084SC01 panel requires careful handling and technical awareness. These are static-sensitive devices, necessitating proper ESD (electrostatic discharge) precautions during installation. The process usually involves disassembling the HMI unit, carefully disconnecting the old panel's ribbon cables and backlight inverter (often CCFL in this generation), and reversing the steps with the new unit.

Attention must be paid to the backlight technology. Older panels like this often use CCFL (Cold Cathode Fluorescent Lamp) backlights, which have a finite lifespan and are distinct from modern LED-backlit units. Understanding the backlight driver compatibility is crucial. Furthermore, technicians should be prepared to potentially adjust the host terminal's settings or firmware to recognize the new display, although a true direct replacement should be plug-and-play.

Future-Proofing and Legacy System Sustainability

The ongoing need for the AA084SC01 highlights a broader theme in industrial automation: the longevity of capital assets. Many factories run systems for 20-30 years, far exceeding the lifecycle of consumer display technology. The availability of exact replacement parts like this panel is essential for minimizing downtime and avoiding costly, full-system upgrades before their planned end-of-life.

This reality drives strategies for future-proofing. Some companies choose to maintain strategic spares of critical components like displays. Others work with suppliers who guarantee long-term support. In some cases, system integrators may offer upgrade kits to newer display technologies, but these often require significant mechanical and electrical adaptation. The AA084SC01, therefore, represents a key component in sustaining the vast installed base of reliable legacy Mitsubishi control systems.

FAQs: AA084SC01 LCD Panel

10. My HMI is very old. Should I just upgrade the whole system?Not necessarily. If the system is otherwise functional, a panel replacement is a cost-effective way to extend its service life for years.

Conclusion

The 8.4" AA084SC01 LCD panel is a quintessential example of a specialized component whose value is defined by its context. Its significance extends far beyond its modest SVGA resolution or 4:3 aspect ratio. It serves as a critical lifeline for maintaining operational continuity in countless industrial facilities relying on proven Mitsubishi automation systems. Understanding its specifications, applications, and the nuances of its sourcing and integration is essential knowledge for those responsible for sustaining these vital assets.

In the world of industrial maintenance, the right component is not merely the one that fits physically, but the one that ensures seamless functional and electrical harmony. The pursuit of the AA084SC01, therefore, is more than a procurement task; it is an exercise in preserving system integrity and protecting long-term industrial investment. As legacy systems continue to form the backbone of modern manufacturing, the role of precise, compatible replacements like this panel remains indispensable.