All Categories

- Industrial LCD display

-

Industrial Products

- DC Servo Drive

- AC Servo Drive

- other

- Heidelberg

- FANUC

- IFM

- Meter

- CCD

- Membrane Keypad

- Film

- YOKOGAWA Module

- Card

- ABB

- MITSUBISHI

- FANUC

- KEYENCE

- BECKHOFF

- Honeywell

- HOLLYSYS

- FUJI servo drives

- HP

- solenoid valve

- thermostat

- Siemens adapter

- color oscilloscope

- Fujitsu connector

- CHELIC

- SMC

- CISCO Module

- INTEL

- Key board

- FAIRCHILD

- Motherboard

- Board

- Bearing

- other

- Control Panel

- Contactor

- Circuit

- OMRON

- Relay

- Controller

- Photoelectric Switch

- Photoelectric Sensor

- Original

- Fan

- Motor Driver

- Limit Switch

- Amplifier

- power supply

- LENZE

- Cable

- Encoder

- Sensor

- Transformer

- Fiber Optic Sensor

- Protection Relay

- Temperature Controller

- Proximity Switch

- Switch Sensor

- Siemens

- Industrial board

- HMI Touch Glass

-

HMI Full Machine Whole unit

- OMRON HMI Touch Panel

- Siemens HMI Touch Panel

- Mitsubishi HMI Touch Panel

- Allen-Bradley automation HMI Touch Panel

- DELTA HMI Touch Panel

- EVIEW DELTA HMI Touch Panel

- KINCO DELTA HMI Touch Panel

- HITECH HMI Touch Panel

- WEINTECK HMI Touch Panel

- TECVIEW HMI Touch Panel

- WEINVIEW HMI Touch Panel

- PRO-FACE HMI Touch Panel

- SIMATIC HMI Touch Panel

- AMPIRE HMI Touch Panel

- HEIDELBERG HMI Touch Panel

- PANASONIC HMI Touch Panel

- PATLITE HMI Touch Panel

- KYOCERA HMI Touch Panel

- KEYENCE HMI Touch Panel

- WEINVIEW HMI Touch Panel

- HITECH HMI Touch Panel

- FUJI HMI Touch Panel

- HAKKO HMI Touch Panel

- SCHNEIDER HMI Touch Panel

- SAMKOON touch panel

- other

- Module

- lcd inverter

- Membrane Keypad Switch

- Winni Touch Screens

- Frequency Inverter

- Servo Motor

- PLC

Recommended Products

Home » News

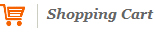

CLAA170EA07 LCD Display Panel Specs

In the intricate world of industrial automation, human-machine interfaces (HMIs) serve as the critical bridge between complex machinery and human operators. At the heart of a reliable HMI lies its display module—a component whose performance directly impacts usability, efficiency, and system uptime. This article delves into a specific and pivotal component in this landscape: the CLAA170EA07 LCD display. This 17-inch TFT-LCD panel is not merely a screen; it is a specialized tool engineered for demanding environments.

Our exploration will move beyond basic specifications to uncover the technical DNA, application rationale, and integration nuances of this display. We will dissect its core characteristics, understand the environments it is built to conquer, and compare it within the broader market ecosystem. For engineers, system integrators, and procurement specialists, this deep dive aims to provide a comprehensive resource, transforming the CLAA170EA07 from a part number into a well-understood solution for industrial visualization challenges.

Technical Anatomy and Core Specifications

The CLAA170EA07 is a 17-inch diagonal TFT-LCD module utilizing an a-Si (amorphous Silicon) active matrix technology. Its native resolution of 1280 x 1024 pixels (SXGA) offers a 5:4 aspect ratio, a format historically prevalent in industrial and medical equipment, ensuring compatibility with legacy systems and providing ample vertical space for data-rich interfaces. The panel employs LVDS (Low-Voltage Differential Signaling) interface technology, which ensures robust data transmission with minimal electromagnetic interference—a critical factor in electrically noisy industrial settings.

Key performance parameters include its brightness, typically around 300 nits or higher, which ensures readability under controlled or moderately bright indoor lighting. Its contrast ratio defines the depth between blacks and whites, crucial for text and graphic clarity. Furthermore, the module specifies a defined range of horizontal and vertical viewing angles, ensuring that information remains visible to operators who may not be directly in front of the display. Understanding these specifications is the first step in evaluating its suitability for a project.

The Industrial-Grade Design Philosophy

What distinguishes the CLAA170EA07 from a commercial desktop monitor is its underlying design philosophy focused on reliability and longevity. Industrial-grade components are selected for their ability to withstand extended operational hours, often 24/7, without failure. The backlight system, typically utilizing CCFL (Cold Cathode Fluorescent Lamp) technology in this generation of displays, is rated for tens of thousands of hours of life.

The module is designed to operate reliably across a wider temperature range (e.g., 0°C to 50°C or beyond) compared to consumer goods. Its construction considers resistance to vibration, dust, and humidity fluctuations commonly found on factory floors. This robustness minimizes downtime and maintenance costs, translating to a lower total cost of ownership despite a potentially higher initial investment than a commercial panel. The design prioritizes consistent performance over flashy features.

Primary Application Environments and Use Cases

The inherent robustness of the CLAA170EA07 makes it a preferred choice for environments where failure is not an option. It is commonly integrated into Factory Automation HMIs, serving as the visual interface for PLCs (Programmable Logic Controllers) on assembly lines, packaging machinery, and robotic control stations. In the medical field, it finds application in diagnostic equipment and patient monitoring systems, where accuracy and reliability are paramount.

Beyond manufacturing and healthcare, this display module is suited for kiosks, point-of-sale systems, and transportation control panels. Its SXGA resolution is ideal for displaying technical drawings, schematic diagrams, and dense tables of numerical data. In each case, the display acts as a durable window into the machine's process, enabling precise monitoring and control while enduring the physical and operational stresses of its installed environment.

Integration Considerations and System Compatibility

Successfully deploying the CLAA170EA07 requires careful attention to integration details. Engineers must ensure compatibility between the panel's LVDS interface and the controller board's output signal. This involves matching the pin assignment, voltage levels, and data lane configuration. The power supply requirements for the CCFL backlight inverter must also be meticulously planned, as improper power can drastically reduce backlight lifespan.

Mechanical integration is equally critical. The module's dimensions, bezel size, and mounting hole patterns must align with the chassis design. Furthermore, considerations for thermal management are essential; even robust components need adequate ventilation to dissipate heat over continuous operation. Proper ESD (Electrostatic Discharge) protection during handling and installation is mandatory to prevent latent damage to the delicate LCD drivers and transistors.

Market Context and Comparison with Alternatives

Within the industrial display ecosystem, the CLAA170EA07 represents a specific tier—a reliable, mature technology product. Its primary alternatives include other 17-inch SXGA panels from different manufacturers and the newer wave of LED-backlit modules. LED backlighting offers advantages such as thinner profiles, lower power consumption, and a wider operating temperature range, and is becoming the new standard.

However, the CLAA170EA07 and its CCFL-based counterparts remain relevant in cost-sensitive applications, for direct replacement in legacy systems, or where a specific brightness/color performance characteristic is required. When comparing, one must evaluate not just cost per unit, but also long-term availability, supply chain stability, and the total cost of redesigning a system to accommodate a different form factor or interface.

Longevity, Sourcing, and Future-Proofing Strategies

Industrial equipment often has a lifecycle exceeding a decade, making component longevity a top concern. The production lifespan of a specific LCD module like the CLAA170EA07 is finite. Therefore, developing a sourcing and obsolescence management strategy is crucial for product managers. This involves identifying authorized distributors, considering aftermarket suppliers for end-of-life stock, and evaluating form-fit-function compatible replacements.

Future-proofing involves designing systems with modularity in mind, allowing for display upgrades with minimal redesign. It also means staying informed about technology trends, such as the transition to LED backlighting and higher resolutions, to plan for eventual migration. For ongoing projects, securing a lifetime buy of critical components or having validated alternate part numbers on file are prudent risk mitigation practices.

FAQs: CLAA170EA07 LCD Display

1. What is the CLAA170EA07?A 17-inch industrial TFT-LCD module with SXGA (1280x1024) resolution and CCFL backlight, commonly used in HMIs.

2. What is its primary interface?It typically uses an LVDS (Low-Voltage Differential Signaling) interface for robust data transmission.

3. Where is it commonly used?In factory automation, medical equipment, kiosks, POS systems, and other demanding environments requiring reliable displays.

4. What does "industrial-grade" mean for this display?It denotes extended lifespan (often 24/7 operation), wider operating temperature ranges, and construction for vibration/dust resistance.

5. Is it a touchscreen?No, the CLAA170EA07 is a display panel only. Touch functionality (resistive, capacitive) would be added as a separate overlay.

6. What is the main drawback of its CCFL backlight?Compared to LED, CCFL is generally thicker, consumes more power, has a narrower temperature range, and may have a shorter lifespan.

7. How do I power the backlight?A CCFL backlight requires a high-voltage AC inverter. The power specifications must be matched precisely to the module's requirements.

8. Is this display still being manufactured?It may be in sustained production or at an end-of-life stage, depending on the manufacturer. Checking with distributors is essential.

9. What are key integration pitfalls to avoid?Mismatched LVDS pinouts, improper backlight inverter voltage/current, inadequate heat dissipation, and poor ESD handling.

10. What should I consider for a replacement?Seek a form-fit-function compatible module, prioritizing interface (LVDS), mounting holes, dimensions, and electrical characteristics.

Conclusion

The CLAA170EA07 LCD display module exemplifies the engineering priorities of the industrial sector: reliability, clarity, and durability over consumer-oriented aesthetics. Its value is not defined by cutting-edge specs, but by its proven ability to perform consistently in critical applications where system failure carries significant cost or risk. Understanding its technical foundations, ideal use cases, and integration requirements allows professionals to deploy it effectively.

As technology evolves, with LED backlighting and higher resolutions becoming standard, modules like the CLAA170EA07 will continue to serve vital roles in maintaining existing systems and in applications where its specific performance profile remains optimal. The ultimate lesson it offers is that in industrial design, the choice of a component is a strategic decision, balancing immediate technical needs with long-term supply chain and lifecycle management.