- Industrial LCD display

-

Industrial Products

- DC Servo Drive

- AC Servo Drive

- other

- Heidelberg

- FANUC

- IFM

- Meter

- CCD

- Membrane Keypad

- Film

- YOKOGAWA Module

- Card

- ABB

- MITSUBISHI

- FANUC

- KEYENCE

- BECKHOFF

- Honeywell

- HOLLYSYS

- FUJI servo drives

- HP

- solenoid valve

- thermostat

- Siemens adapter

- color oscilloscope

- Fujitsu connector

- CHELIC

- SMC

- CISCO Module

- INTEL

- Key board

- FAIRCHILD

- Motherboard

- Board

- Bearing

- other

- Control Panel

- Contactor

- Circuit

- OMRON

- Relay

- Controller

- Photoelectric Switch

- Photoelectric Sensor

- Original

- Fan

- Motor Driver

- Limit Switch

- Amplifier

- power supply

- LENZE

- Cable

- Encoder

- Sensor

- Transformer

- Fiber Optic Sensor

- Protection Relay

- Temperature Controller

- Proximity Switch

- Switch Sensor

- Siemens

- Industrial board

- HMI Touch Glass

-

HMI Full Machine Whole unit

- OMRON HMI Touch Panel

- Siemens HMI Touch Panel

- Mitsubishi HMI Touch Panel

- Allen-Bradley automation HMI Touch Panel

- DELTA HMI Touch Panel

- EVIEW DELTA HMI Touch Panel

- KINCO DELTA HMI Touch Panel

- HITECH HMI Touch Panel

- WEINTECK HMI Touch Panel

- TECVIEW HMI Touch Panel

- WEINVIEW HMI Touch Panel

- PRO-FACE HMI Touch Panel

- SIMATIC HMI Touch Panel

- AMPIRE HMI Touch Panel

- HEIDELBERG HMI Touch Panel

- PANASONIC HMI Touch Panel

- PATLITE HMI Touch Panel

- KYOCERA HMI Touch Panel

- KEYENCE HMI Touch Panel

- WEINVIEW HMI Touch Panel

- HITECH HMI Touch Panel

- FUJI HMI Touch Panel

- HAKKO HMI Touch Panel

- SCHNEIDER HMI Touch Panel

- SAMKOON touch panel

- other

- Module

- lcd inverter

- Membrane Keypad Switch

- Winni Touch Screens

- Frequency Inverter

- Servo Motor

- PLC

-

AA084XD01 Mitsubishi 8.4inch lcd display

¥18896.64

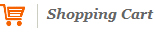

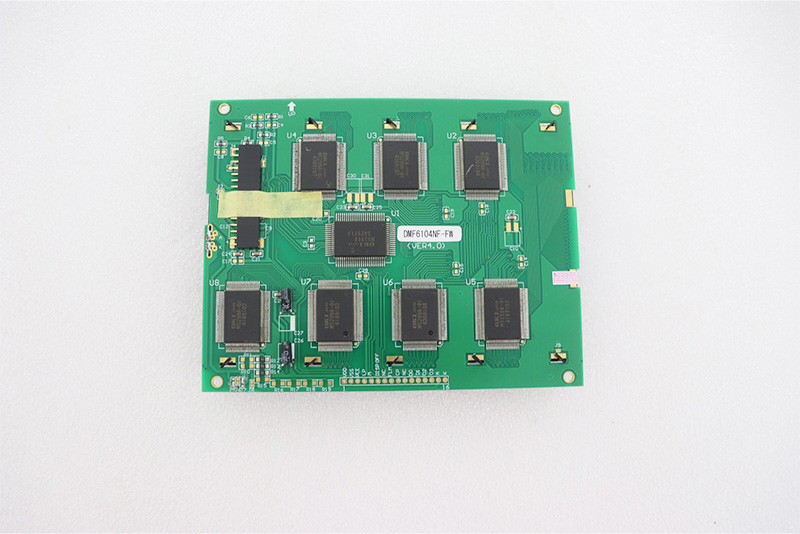

DMF6104NF-FW OPTREX 5.3-inch CCFL LCD display

Our exploration will move beyond basic datasheet specifications to uncover the practical implications of its technology, design, and application. We will dissect the characteristics of its Cold Cathode Fluorescent Lamp (CCFL) backlighting, a technology that defined an era of industrial displays. By examining its electrical interface, mechanical robustness, and environmental specifications, we aim to provide a comprehensive guide for engineers, procurement specialists, and system integrators. This analysis will equip you with the knowledge to determine if the DMF6104NF-FW remains a viable solution for modern applications or represents a legacy technology in a world rapidly shifting towards LEDs.

The Core Technology: Understanding the 5.3-inch CCFL TFT LCD

However, the defining technological feature of this module is its Cold Cathode Fluorescent Lamp (CCFL) backlight system. Unlike modern LED backlights, CCFL technology relies on a mercury-vapor-filled glass tube that emits light when a high-voltage alternating current is applied. This method produces a bright, diffuse, and historically very stable white light with excellent uniformity across the screen area. The "FW" suffix in the part number typically denotes a wide-temperature range version, hinting at the component's design for challenging environments where thermal consistency is crucial for the backlight's performance and longevity.

Illumination Architecture: The Role and Characteristics of CCFL Backlighting

This architecture, however, introduces specific design complexities. A CCFL tube requires an inverter circuit to generate the high AC voltage (often hundreds to thousands of volts) needed for operation. This inverter adds to the module's power consumption, component count, and potential points of failure. Furthermore, CCFLs contain a small amount of mercury, raising environmental and disposal concerns that have accelerated the industry-wide shift to LED alternatives. The light output also tends to have a specific spectral quality and dimming methodology that differs from LED systems.

Electrical and Signal Interface: Integration into Host Systems

Power requirements are twofold. The TFT panel logic and LVDS receiver operate on a low-voltage DC supply (commonly 3.3V or 5V). Crucially, the CCFL backlight requires a separate high-voltage AC power source, provided by the aforementioned inverter. This inverter may be onboard the module's controller PCB or be an external component. System designers must account for both power rails and the potential electromagnetic interference generated by the high-frequency inverter circuit, which may necessitate shielding in sensitive applications.

Mechanical and Environmental Design for Robustness

The environmental specifications are where its ruggedness truly shines. The wide-temperature variant (FW) is engineered to operate reliably across an extended range, often from -30°C to +80°C for the panel, with the CCFL backlight having its own, slightly narrower operational temperature window. This ensures performance in freezing cold storage facilities or hot manufacturing plants. Additionally, these modules are often specified with high resistance to vibration and shock, critical for mobile or heavy machinery applications.

Application Scenarios: Where the DMF6104NF-FW Excels

Other key arenas include point-of-sale (POS) systems, transportation infotainment, and specialized instrumentation. In these use cases, the long operational life of a well-driven CCFL (often rated for 30,000 to 50,000 hours) and its resistance to performance degradation over time were significant advantages. It is particularly suited for products with long lifecycles where a stable, proven supply chain for repair and maintenance is essential.

Legacy Consideration: CCFL vs. Modern LED Backlighting

Consequently, the DMF6104NF-FW is now largely considered a legacy product. While it may still be in production or available through distributors for sustaining existing equipment, new designs almost universally opt for LED modules. The decision to use or replace the DMF6104NF-FW hinges on factors like system longevity requirements, the cost and risk of redesign, and the availability of direct "drop-in" LED upgrades that match its form factor and electrical interface, allowing for a straightforward technology transition without a complete system overhaul.

FAQs: DMF6104NF-FW OPTREX 5.3-inch CCFL LCD Display

10. Where can I find technical specifications for the DMF6104NF-FW?Search for the official datasheet from Optrex (now part of Densitron Technologies) or through authorized electronic component distributors.