- Industrie-LCD-Display

-

Industrial Products

- DC Servo Drive

- AC Servo Drive

- other

- Heidelberg

- FANUC

- IFM

- Meter

- CCD

- Membrane Keypad

- Film

- YOKOGAWA

- Card

- ABB

- MITSUBISHI

- FANUC

- KEYENCE

- BECKHOFF

- Honeywell

- HOLLYSYS

- FUJI servo drives

- HP

- solenoid valve

- thermostat

- Siemens adapter

- color oscilloscope

- Fujitsu connector

- CHELIC

- SMC

- CISCO

- INTEL

- Key board

- FAIRCHILD

- Der Aufsichtsrat

- Board

- Bearing

- other

- Control Panel

- Contactor

- Circuit

- Omron

- Relais.

- Der controller

- Optoelektronische schalter

- Optoelektronische sensoren

- Original

- Fan

- Motortreiber

- Endschalter

- Verstärker

- power supply

- LENZE

- Cable

- Encoder

- Sensor

- Transformator

- Fiber Optic Sensor

- Schutzrelais

- Temperaturregler

- Näherungsschalter

- Switch Sensor

- Siemens

- PCB

- HMI Touch-Glas

-

HMI-Vollautomat Ganze Einheit

- OMRON HMI Touch Panel

- Siemens HMI Touch Panel

- Mitsubishi HMI Touch Panel

- Allen-Bradley Automatisierung HMI Touch

- DELTA HMI Touch Panel

- EVIEW DELTA HMI Touch Panel

- KINCO DELTA HMI Touch Panel

- HITECH HMI Touch Panel

- WEINTECK HMI Touch Panel

- TECVIEW HMI Touch Panel

- WEINVIEW HMI Touch Panel

- PRO-FACE HMI Touch Panel

- SIMATIC HMI Touch Panel

- AMPIRE HMI Touch Panel

- HEIDELBERG HMI Touch Panel

- PANASONIC HMI Touch Panel

- PATLITE HMI Touch Panel

- KYOCERA HMI Touch Panel

- KEYENCE HMI Touch Panel

- WEINVIEW HMI Touch Panel

- HITECH HMI Touch Panel

- FUJI HMI Touch Panel

- HAKKO HMI Touch Panel

- SCHNEIDER HMI Touch Panel

- SAMKOON touch panel

- andere

- Module

- LCD Wechselrichter

- Membran Tastenfeld Schalter

- Winni Touch Screens

- Frequenzumrichter

- Servo Motor

- PLC

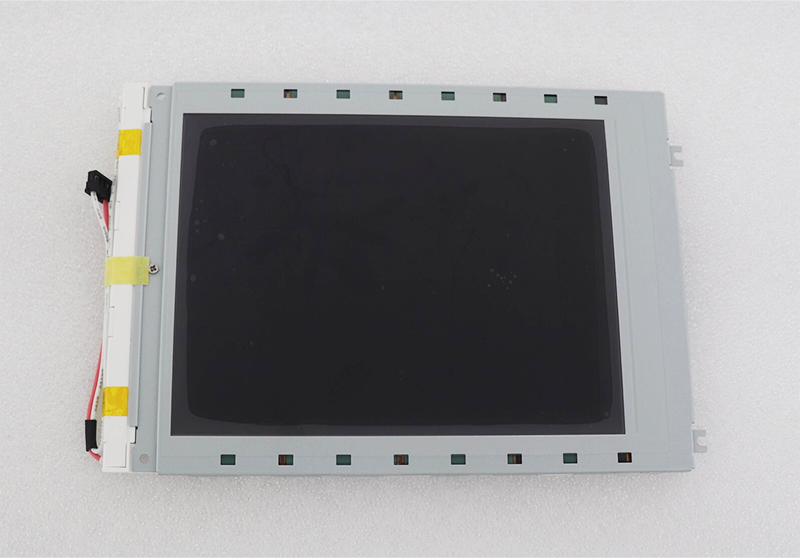

DMF-50383NF-FW OPTREX 7.2" LCD Display Screen

Our exploration moves beyond basic datasheet specifications to uncover the practical implications of integrating this display into real-world applications. We will analyze its core technological attributes, from the TFT active matrix and LED backlighting to its robust mechanical design. The discussion will progress to its performance in challenging environments, its electrical interface nuances, and the critical software considerations for driving the screen. Finally, we will assess its ideal application landscapes and the tangible value it brings to product developers. This comprehensive guide aims to equip engineers, procurement specialists, and product managers with the deep, actionable insights needed to make an informed decision on this versatile display solution.

Core Technology and Construction

Physically, the module is constructed with durability in mind. It features a robust metal frame that protects the delicate glass substrate from mechanical stress and vibration. The surface is typically fitted with a hard-coated or anti-glare polarizer, enhancing readability under various lighting conditions and offering resistance to scratches. The integration of a white LED backlight system provides uniform, bright illumination with high efficiency and long lifespan, which is crucial for devices expected to operate continuously for thousands of hours.

Performance in Demanding Environments

Beyond temperature, the display's construction mitigates other environmental challenges. The sealed front surface helps resist dust and moisture ingress. Furthermore, the optical bonding option (often available for such modules) laminates the cover glass directly to the LCD, which not only improves optical clarity by reducing internal reflection but also significantly enhances mechanical strength. This makes the display far more resistant to shock and vibration, a common occurrence in automotive, transportation, and heavy machinery applications where reliability is non-negotiable.

Electrical Interface and Power Considerations

Power design is another critical aspect. The module requires a stable logic voltage supply (often 3.3V) and a separate, higher voltage for the LED backlight driver. Designers must implement proper power sequencing and in-rush current limiting to prevent damage during startup. The efficiency of the LED backlight directly impacts overall system power consumption. Modern drivers allow for Pulse-Width Modulation (PWM) dimming, enabling both brightness control and additional power savings, which is vital for battery-powered portable devices.

Software Integration and Driver Support

Initialization is also crucial. Most TFT modules contain an internal register set that must be properly configured via an SPI or I2C interface to power up the display IC and set parameters like color depth and scanning direction. Lack of driver support can lead to significant development delays. Therefore, selecting a module from a reputable manufacturer like OPTREX, which typically provides comprehensive initialization code examples and documentation for popular embedded platforms, can drastically reduce time-to-market and mitigate integration risks.

Ideal Application Landscapes

Furthermore, its characteristics are well-suited for medical devices (patient monitors, diagnostic equipment), point-of-sale (POS) terminals, and kiosks. In these applications, the 7.2-inch size offers a compact yet sufficiently large canvas for interactive menus, data visualization, and transaction information. The module's ability to deliver consistent performance over many years aligns perfectly with the long lifecycle expectations of professional and industrial equipment.

Total Cost of Ownership and Value Proposition

Additionally, the comprehensive technical support and reliable documentation lower engineering integration costs and accelerate development cycles. When compared to consumer-grade screens that may fail prematurely in harsh conditions, the higher initial investment in a ruggedized, reliable module like this one translates directly into lower lifecycle costs, enhanced brand reputation for reliability, and reduced long-term risk for the end-product manufacturer.

FAQs

Q10: Where can I find technical documentation and driver examples?A10: Full datasheets, application notes, and often initialization code are available directly from OPTREX or authorized distributors.