- Industrie-LCD-Display

-

Industrial Products

- DC Servo Drive

- AC Servo Drive

- other

- Heidelberg

- FANUC

- IFM

- Meter

- CCD

- Membrane Keypad

- Film

- YOKOGAWA

- Card

- ABB

- MITSUBISHI

- FANUC

- KEYENCE

- BECKHOFF

- Honeywell

- HOLLYSYS

- FUJI servo drives

- HP

- solenoid valve

- thermostat

- Siemens adapter

- color oscilloscope

- Fujitsu connector

- CHELIC

- SMC

- CISCO

- INTEL

- Key board

- FAIRCHILD

- Der Aufsichtsrat

- Board

- Bearing

- other

- Control Panel

- Contactor

- Circuit

- Omron

- Relais.

- Der controller

- Optoelektronische schalter

- Optoelektronische sensoren

- Original

- Fan

- Motortreiber

- Endschalter

- Verstärker

- power supply

- LENZE

- Cable

- Encoder

- Sensor

- Transformator

- Fiber Optic Sensor

- Schutzrelais

- Temperaturregler

- Näherungsschalter

- Switch Sensor

- Siemens

- PCB

- HMI Touch-Glas

-

HMI-Vollautomat Ganze Einheit

- OMRON HMI Touch Panel

- Siemens HMI Touch Panel

- Mitsubishi HMI Touch Panel

- Allen-Bradley Automatisierung HMI Touch

- DELTA HMI Touch Panel

- EVIEW DELTA HMI Touch Panel

- KINCO DELTA HMI Touch Panel

- HITECH HMI Touch Panel

- WEINTECK HMI Touch Panel

- TECVIEW HMI Touch Panel

- WEINVIEW HMI Touch Panel

- PRO-FACE HMI Touch Panel

- SIMATIC HMI Touch Panel

- AMPIRE HMI Touch Panel

- HEIDELBERG HMI Touch Panel

- PANASONIC HMI Touch Panel

- PATLITE HMI Touch Panel

- KYOCERA HMI Touch Panel

- KEYENCE HMI Touch Panel

- WEINVIEW HMI Touch Panel

- HITECH HMI Touch Panel

- FUJI HMI Touch Panel

- HAKKO HMI Touch Panel

- SCHNEIDER HMI Touch Panel

- SAMKOON touch panel

- andere

- Module

- LCD Wechselrichter

- Membran Tastenfeld Schalter

- Winni Touch Screens

- Frequenzumrichter

- Servo Motor

- PLC

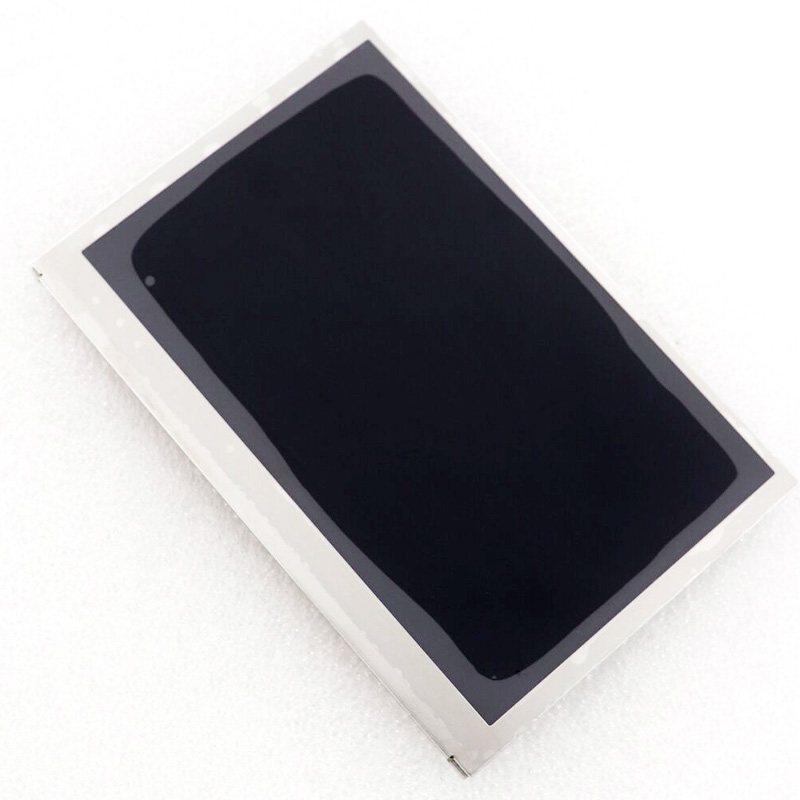

Mitsubishi AA050ME01 LCD Panel, 5.0 Inch 800x480 Display

In the intricate world of industrial and embedded display solutions, specific components become keystones for entire product lines. The 5.0-inch MITSUBISHI AA050ME01 LCD panel is one such critical component. This display module, characterized by its 800 x 480 (WVGA) resolution and robust design, is far more than a simple screen; it is a precision-engineered interface found in demanding environments from factory floors to medical devices. This article delves deep into the technical essence and practical applications of the AA050ME01, moving beyond basic specifications to explore why it remains a sought-after solution.

Understanding this panel is crucial for engineers, procurement specialists, and product developers. We will dissect its core technology, interface protocols, mechanical design, and the specific application niches where it excels. Furthermore, we will address integration challenges and provide guidance on sourcing and lifecycle considerations. This comprehensive analysis aims to equip professionals with the knowledge needed to effectively evaluate, specify, and integrate this distinguished Mitsubishi display into their projects.

Unpacking the Core Technology: TFT-LCD and WVGA Resolution

The foundation of the AA050ME01 is its a-Si (amorphous Silicon) TFT-LCD (Thin-Film Transistor Liquid Crystal Display) technology. This mature and reliable technology provides a sharp, stable image by using a transistor for each pixel, allowing for precise control of brightness and color. The 800 x 480 pixel array, known as Wide VGA (WVGA), offers a 15:9 aspect ratio. This wider format is particularly advantageous for displaying modern user interfaces, diagnostic data, or control panels, providing more horizontal space without excessively increasing the panel's vertical dimension.

Beyond resolution, the panel's optical performance is defined by its brightness, contrast ratio, and viewing angle. Typically designed for high-brightness operation, it ensures readability under various ambient lighting conditions, including indoor industrial settings. The viewing angle, often specified using the IPS (In-Plane Switching) or similar wide-view technology in such industrial panels, guarantees consistent color and contrast even when viewed from off-axis positions, a critical feature for multi-operator stations or devices viewed from different angles.

Interface and Signal Integration: The LVDS Standard

The AA050ME01 panel typically utilizes an LVDS (Low-Voltage Differential Signaling) interface. This is a pivotal aspect of its design for industrial applications. LVDS is a high-speed digital interface known for its robustness against electromagnetic interference (EMI). It transmits data using differential pairs (two wires per signal), where the information is encoded as the voltage difference between them. This method inherently cancels out noise picked up along the cable run, ensuring signal integrity over longer distances and in electrically noisy environments like those near heavy machinery.

Integrating this panel requires a compatible LVDS transmitter on the host system's mainboard or controller. The interface defines the color depth (often 18-bit or 24-bit RGB), synchronization signals, and power requirements. Understanding the pinout and timing parameters of the LVDS interface is essential for a successful design-in. Engineers must ensure their controller can drive the panel's native resolution and refresh rate to avoid flicker or image artifacts, making the interface a key consideration in the system's overall architecture.

Mechanical Design and Environmental Robustness

The mechanical construction of the AA050ME01 is tailored for integration and durability. The module usually consists of the LCD glass, backlight unit (LED-based for longevity and low power), and driver electronics, all assembled into a rigid metal frame. This frame provides structural integrity, protects sensitive components, and offers standardized mounting points. Precise mechanical drawings specifying the active area, overall dimensions, bezel size, and mounting hole positions are critical for designing the product's front enclosure.

While specific ratings depend on the exact module variant and any additional sealing, industrial panels like this are often engineered to withstand challenging conditions. This can include extended operating temperature ranges (e.g., -20°C to +70°C), resistance to vibration, and sometimes enhanced humidity tolerance. The choice of surface treatment for the polarizer, such as anti-glare (AG) or hard coating (HC), is also part of the mechanical specification, directly impacting usability under bright lights and resistance to scratches.

Primary Application Domains and Use Cases

The technical profile of the AA050ME01 makes it ideal for embedded systems where reliability and clarity are non-negotiable. A primary domain is industrial human-machine interfaces (HMIs) for PLCs, CNC machines, and process control systems. Here, the display presents real-time metrics, control buttons, and alarm statuses to operators. Its readability and robustness are paramount.

Another significant application is in the medical device field, for patient monitoring equipment, diagnostic instruments, or portable medical carts. The combination of stable performance, good image quality, and proven reliability aligns with stringent medical equipment requirements. Additionally, this panel finds use in transportation (e.g., in-vehicle infotainment or control systems for commercial vehicles), test and measurement equipment, and specialized point-of-sale (POS) or kiosk terminals operating in demanding environments.

Integration Considerations and Potential Challenges

Successfully integrating the AA050ME01 involves several technical considerations beyond simple electrical connection. Power sequencing is crucial: the various voltage rails for the logic, TFT array, and backlight must be applied and removed in a specific order to prevent latch-up or damage to the LCD cells. The backlight driver circuit requires careful design; while the backlight LEDs may have a long life, the driver must provide constant current and may include dimming functionality via PWM (Pulse-Width Modulation).

Potential challenges include managing electromagnetic compatibility (EMC), as the high-speed LVDS lines can be both victims and sources of EMI. Proper board layout, shielding, and cable selection are necessary. Furthermore, as a potentially discontinued or mature product, sourcing compatible interface cables and connectors (like the standard FPC/FFC connectors used) may require attention. Engineers must also design the software driver to correctly initialize the panel's timing controller (TCON).

Sourcing, Alternatives, and Lifecycle Management

The AA050ME01 is a Mitsubishi Electric part, and as with many industrial components, it may have a long but finite production lifecycle. Original equipment manufacturers (OEMs) often source these panels through authorized distributors or specialized electronic component suppliers. It is vital to verify the authenticity of the module, as counterfeit displays can plague the market, offering inferior performance and reliability.

For new designs, engineers should check the official manufacturer's status (active, discontinued, last buy). If facing obsolescence, identifying a form-fit-function compatible alternative is a common strategy. This involves finding another 5.0-inch WVGA LVDS panel with identical mechanical outlines, mounting holes, and electrical interfaces. Several other manufacturers produce panels in this standard industrial footprint. Lifecycle management planning, including considering last-time buys or qualifying a second source early, is essential for products with long deployment periods.

FAQs: Mitsubishi AA050ME01 LCD Panel

10. What connectors does it use?It generally uses standard FPC (Flexible Printed Circuit) or FFC (Flat Flexible Cable) connectors for the LVDS and backlight signals.

Conclusion

The Mitsubishi AA050ME01 5.0-inch LCD panel exemplifies the engineering principles required for reliable embedded display solutions. Its combination of WVGA resolution, robust LVDS interface, and industrial-grade mechanical design has cemented its role in critical applications across multiple sectors. This analysis has moved beyond part numbers to explore the technological rationale behind its features, the practicalities of integration, and the strategic considerations for sourcing and lifecycle management.

For professionals, understanding a component at this depth is invaluable. It enables informed decision-making, whether selecting a display for a new product, maintaining an existing system, or navigating component obsolescence. The AA050ME01 serves as a case study in how a well-designed, standardized display module can become a trusted and enduring component in the world of industrial electronics, where performance and reliability are the ultimate benchmarks of value.