- Industrial LCD display

-

Industrial Products

- DC Servo Drive

- AC Servo Drive

- other

- Heidelberg

- FANUC

- IFM

- Meter

- CCD

- Membrane Keypad

- Film

- YOKOGAWA Module

- Card

- ABB

- MITSUBISHI

- FANUC

- KEYENCE

- BECKHOFF

- Honeywell

- HOLLYSYS

- FUJI servo drives

- HP

- solenoid valve

- thermostat

- Siemens adapter

- color oscilloscope

- Fujitsu connector

- CHELIC

- SMC

- CISCO Module

- INTEL

- Key board

- FAIRCHILD

- Motherboard

- Board

- Bearing

- other

- Control Panel

- Contactor

- Circuit

- OMRON

- Relay

- Controller

- Photoelectric Switch

- Photoelectric Sensor

- Original

- Fan

- Motor Driver

- Limit Switch

- Amplifier

- power supply

- LENZE

- Cable

- Encoder

- Sensor

- Transformer

- Fiber Optic Sensor

- Protection Relay

- Temperature Controller

- Proximity Switch

- Switch Sensor

- Siemens

- Industrial board

- HMI Touch Glass

-

HMI Full Machine Whole unit

- OMRON HMI Touch Panel

- Siemens HMI Touch Panel

- Mitsubishi HMI Touch Panel

- Allen-Bradley automation HMI Touch Panel

- DELTA HMI Touch Panel

- EVIEW DELTA HMI Touch Panel

- KINCO DELTA HMI Touch Panel

- HITECH HMI Touch Panel

- WEINTECK HMI Touch Panel

- TECVIEW HMI Touch Panel

- WEINVIEW HMI Touch Panel

- PRO-FACE HMI Touch Panel

- SIMATIC HMI Touch Panel

- AMPIRE HMI Touch Panel

- HEIDELBERG HMI Touch Panel

- PANASONIC HMI Touch Panel

- PATLITE HMI Touch Panel

- KYOCERA HMI Touch Panel

- KEYENCE HMI Touch Panel

- WEINVIEW HMI Touch Panel

- HITECH HMI Touch Panel

- FUJI HMI Touch Panel

- HAKKO HMI Touch Panel

- SCHNEIDER HMI Touch Panel

- SAMKOON touch panel

- other

- Module

- lcd inverter

- Membrane Keypad Switch

- Winni Touch Screens

- Frequency Inverter

- Servo Motor

- PLC

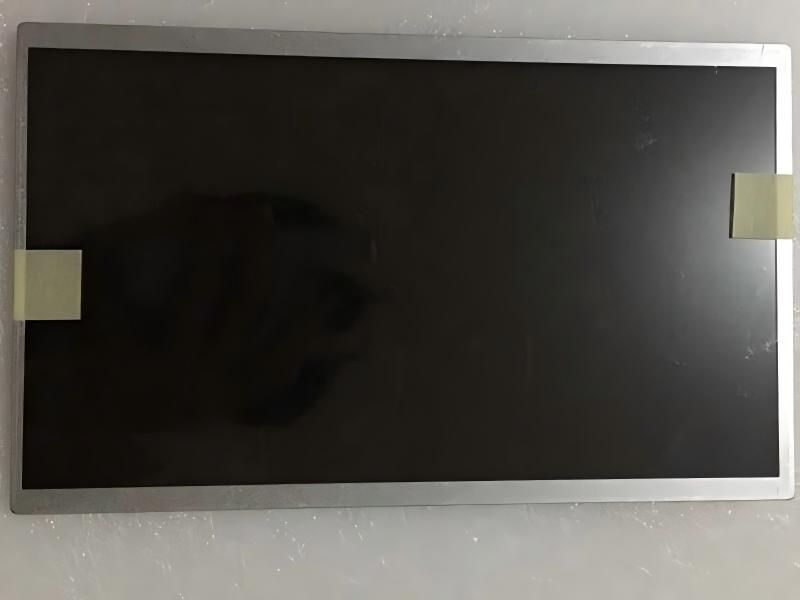

AC101TB01 Mitsubishi 10.1INCH 1280*800 LCD PANEL

In the intricate world of industrial automation and specialized display applications, the choice of a human-machine interface (HMI) panel is a critical decision that impacts system reliability, operator efficiency, and long-term performance. At the heart of many sophisticated control systems lies a component like the AC101TB01 Mitsubishi 10.1-inch LCD Panel. This is not a consumer-grade monitor; it is a purpose-built industrial display module designed to meet the rigorous demands of factory floors, medical equipment, and transportation systems. Its specifications—a 10.1-inch diagonal with a 1280 x 800 (WXGA) resolution—represent a specific balance of size, clarity, and compatibility that has made it a recurring component in various OEM designs.

This article delves beyond the basic datasheet to explore the AC101TB01 in depth. We will examine its technical architecture, the rationale behind its key specifications, and its ideal application environments. Furthermore, we will discuss the critical considerations for integration, maintenance, and sourcing, providing a comprehensive resource for engineers, system integrators, and procurement specialists who need to understand not just what this panel is, but how and where it creates value in real-world industrial scenarios.

Decoding the Specifications: More Than Just Numbers

The AC101TB01 presents a set of specifications that define its core capabilities. The 10.1-inch screen size, measured diagonally, is a proven standard for compact yet readable HMIs, fitting into control panels without excessive space consumption. The 1280 x 800 pixel resolution, known as WXGA, offers a 16:10 aspect ratio. This provides a slightly taller workspace compared to the common 16:9 format, which can be advantageous for displaying longer data lists, diagnostic logs, or control sequences without excessive scrolling.

Understanding the panel's native resolution is crucial for image quality. Driving the display at any resolution other than its native 1280x800 will result in scaled, often blurry, imagery. Typically utilizing LVDS (Low-Voltage Differential Signaling) interface technology, this panel ensures high-speed data transmission with reduced noise interference—a vital feature in electrically noisy industrial environments. These technical choices collectively define the sharpness, stability, and signal integrity of the visual output.

The Industrial Design Philosophy: Built for Endurance

What truly distinguishes the AC101TB01 from a commercial display is its underlying design philosophy focused on reliability and longevity. Industrial panels are engineered for continuous operation, often in 24/7 shift environments. They are built to withstand a wider range of operating temperatures, resist vibrations from machinery, and maintain performance despite fluctuations in power quality.

The backlighting system, often utilizing LED arrays, is selected for its long life and consistent brightness over tens of thousands of hours. The panel's construction considers thermal management to prevent overheating in enclosed spaces. Furthermore, the glass surface and polarizing filters are typically chosen for durability and readability under various lighting conditions, including direct sunlight or dark factory floors. This ruggedized approach ensures the display remains a dependable point of interaction throughout the lifespan of the host equipment.

Primary Application Landscapes: Where This Panel Excels

The AC101TB01 finds its home in environments where performance trumps aesthetics. A primary application is within industrial automation and control systems. It serves as the visual interface for PLCs (Programmable Logic Controllers) in manufacturing lines, robotics control stations, and SCADA (Supervisory Control and Data Acquisition) systems, displaying real-time process data, alarms, and control buttons.

Beyond the factory, this panel is suitable for medical diagnostic equipment, where accurate color representation and high reliability are non-negotiable for patient safety. It is also employed in transportation and infrastructure, such as in-vehicle information systems for trains or buses, and monitoring displays for utility control centers. In each case, the panel's standard size, reliable interface, and robust build make it a preferred "off-the-shelf" module for OEMs designing specialized equipment.

Integration Considerations and Compatibility Challenges

Successfully integrating a module like the AC101TB01 requires careful planning. The first step is interface compatibility. An integrator must ensure their controller board outputs an LVDS signal that matches the panel's pin configuration, voltage requirements, and timing characteristics. This often requires a specific LCD controller board or a custom-designed interface circuit.

Physical integration involves designing a bezel or chassis that securely mounts the panel, connects it to power, and protects its edges. Considerations for heat dissipation must be addressed, as improper thermal design can drastically shorten the backlight's life. Additionally, the choice of a compatible touchscreen overlay (if required), such as resistive or projected capacitive, adds another layer of technical matching. Failure to address these integration details can lead to image artifacts, intermittent faults, or premature failure.

Sourcing, Alternatives, and the Aftermarket Landscape

As a component originally designed for OEM production runs, the AC101TB01 may be sourced through authorized industrial distributors or, more commonly, through the specialized electronic components aftermarket. Given that end-of-life (EOL) notifications are a reality in industrial electronics, finding reliable suppliers with genuine or compatible-grade stock is a key task for maintenance and repair operations.

When the original module is unavailable, engineers must evaluate alternative panels. A suitable replacement must match not only the physical dimensions and mounting holes but, more critically, the electrical interface, voltage levels, and backlight inverter requirements. "Pin-to-pin compatible" alternatives are highly valued but require thorough testing. This landscape makes relationships with knowledgeable suppliers and a deep understanding of the panel's technical DNA essential for sustainable system support.

Maintenance, Longevity, and Proactive Management

Maximizing the service life of the AC101TB01 involves proactive maintenance strategies. The primary wear component is the LED backlight, whose brightness will gradually degrade over time. Monitoring for dimming or color shift is important for critical displays. Environmental factors are also key; keeping the panel within its specified temperature and humidity ranges and ensuring clean, stable power will prevent stress on its internal components.

Having a clear plan for spare parts management is crucial for minimizing downtime in continuous operations. This includes not just the panel itself, but also compatible interface cables and inverters. For systems where the display is mission-critical, understanding the panel's mean time between failures (MTBF) ratings and planning a replacement schedule before failures occur is a hallmark of professional industrial asset management.

Frequently Asked Questions (FAQs)

Q1: What is the primary interface of the AC101TB01 panel?A1: It typically uses an LVDS (Low-Voltage Differential Signaling) interface for robust, high-speed data transmission.Q2: Is this panel compatible with a standard HDMI or VGA output?A2: No, it requires an intermediate controller board to convert signals from HDMI, VGA, or other sources to the panel's native LVDS signal.Q3: What is the significance of the 1280x800 resolution?A3: This WXGA resolution offers a 16:10 aspect ratio, providing more vertical space for data display compared to common 16:9 screens, which is useful for industrial interfaces.Q4: Can I add a touchscreen to this display module?A4: Yes, compatible resistive or capacitive touchscreen overlays can be added, but they require separate integration and controller support.Q5: What are the most common applications for this panel?A5: It is widely used in industrial HMIs, factory automation controls, medical devices, and transportation information systems.Q6: How do I know if a replacement panel is compatible?A6: You must verify physical dimensions, mounting holes, interface type (LVDS pinout), voltage requirements, and backlight specifications.Q7: What is the typical lifespan of the backlight?A7: LED backlights in such industrial panels are often rated for 50,000 hours or more, but lifespan depends on operating temperature and drive current.Q8: Where can I source the AC101TB01?A8: It is available through specialized industrial electronic component distributors and aftermarket suppliers.Q9: What should I do if my panel fails?A9: First, diagnose the issue (power, interface, backlight). Then, source a compatible replacement, ensuring proper integration parameters are met.

Q10: Is this panel suitable for outdoor use?A10: Not unless specifically specified. Standard versions are for indoor industrial use. Outdoor use requires additional protection against moisture, extreme temperatures, and sunlight.

Conclusion

The Mitsubishi AC101TB01 10.1-inch LCD panel exemplifies the engineered reliability required in professional and industrial settings. Its value extends far beyond its basic specifications of size and resolution, lying deeply in its robust construction, stable LVDS interface, and design for continuous operation. As we have explored, its effective deployment hinges on a thorough understanding of integration requirements, environmental considerations, and the nuances of the industrial component supply chain.

For engineers and system managers, mastering these aspects transforms a simple display module into a cornerstone of a dependable human-machine interface. In an era of rapid technological change, components like the AC101TB01 remind us that in critical applications, proven performance, longevity, and seamless integration often hold greater value than mere novelty. Selecting and maintaining such components with expertise is fundamental to building systems that are not only intelligent but also enduringly trustworthy.